manual air valve

Manual air valves are essential components in pneumatic systems, enabling precise control of airflow. They are widely used in industrial automation and manufacturing processes to regulate pressure and flow manually.

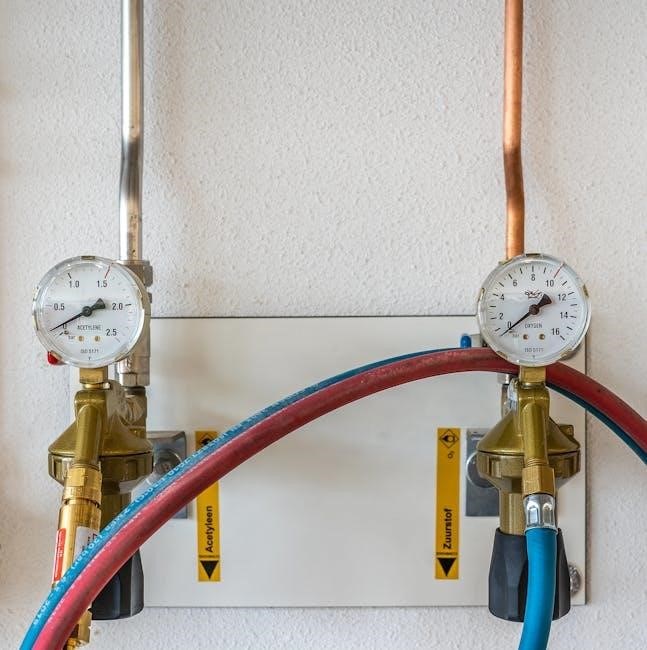

1.1 Definition and Overview

A manual air valve is a device used to control the flow of air in pneumatic systems. It is operated by hand, allowing users to start, stop, or regulate airflow. These valves are essential for maintaining system efficiency and safety. Available in various types, they are designed for specific applications, ensuring precise control over air pressure and flow. Their simplicity and reliability make them indispensable in industries requiring manual operation.

1.2 Importance of Manual Air Valves in Pneumatic Systems

Manual air valves are crucial for controlling airflow in pneumatic systems, ensuring precise operation and safety. They allow operators to regulate pressure and flow, enabling efficient system performance; These valves are vital for isolating components during maintenance and emergency shutdowns. Their reliability and simplicity make them indispensable in industrial automation, automotive, and medical devices. By providing immediate control, manual air valves enhance system reliability and flexibility in various applications.

Types of Manual Air Valves

Manual air valves are categorized into several types, each designed for specific applications. Ball valves, butterfly valves, needle valves, and globe valves are the most common. Ball valves provide on/off control, while butterfly valves offer precise flow regulation. Needle valves enable fine adjustments, and globe valves excel in throttling applications. Each type is tailored to meet unique operational requirements, ensuring efficient airflow management in pneumatic systems. Their design variations make them suitable for diverse industrial and technical needs.

2.1 Ball Valves

Ball valves are a popular type of manual air valve, characterized by their robust design and reliable performance. They feature a rotating ball with a bored center, allowing for precise control of airflow. When the ball is aligned with the flow path, the valve is in the open position, enabling unrestricted airflow. Conversely, when rotated 90 degrees, the valve closes, effectively shutting off the airflow. Ball valves are known for their durability, low maintenance, and ability to handle high pressures, making them ideal for industrial applications where dependability is crucial. They are often preferred in systems requiring quick on/off functionality due to their simple and efficient mechanism of operation.

2.2 Butterfly Valves

Butterfly valves are a versatile type of manual air valve, characterized by their compact design and lightweight construction. They operate using a rotating disc that controls airflow within the system. When the disc is parallel to the flow, the valve is fully open, allowing maximum airflow. When rotated 90 degrees, the valve closes, effectively shutting off the airflow. Butterfly valves are known for their quick operation and are often used in applications where space is limited. They are particularly effective in HVAC systems and industrial processes requiring precise airflow control, offering a reliable and efficient solution for managing air flow.

2.3 Needle Valves

Needle valves are precision control devices used for regulating airflow in pneumatic systems. They feature a tapered needle that moves up and down within a seat, allowing for fine adjustments. These valves are ideal for applications requiring precise flow control, such as in medical devices, laboratory equipment, and industrial systems. The needle valve’s design enables it to handle low-flow applications effectively, making it a crucial component in systems where accuracy and reliability are essential.

2.4 Globe Valves

Globe valves are widely used in pneumatic systems for precise flow control. They operate using a disc that moves up and down within a seat, regulating the airflow effectively. These valves are known for their reliability and durability, making them ideal for applications in HVAC systems, oil and gas industries, and industrial automation. Globe valves are particularly effective in throttling applications, allowing for fine adjustments to airflow, which makes them a versatile choice for systems requiring precise control over air pressure and flow rates.

Working Principle of Manual Air Valves

Manual air valves operate by using a valve stem to control airflow. Turning the handle moves the stem, opening or closing the valve to regulate air pressure and flow.

3.1 Mechanism of Operation

Manual air valves function through a simple yet efficient mechanism. A handle, connected to a valve stem, is turned to move the stem up or down. This motion opens or closes the valve, controlling airflow. In on/off operations, the stem fully opens or shuts the valve, while throttle operations allow partial opening for precise flow control. The valve seat ensures a tight seal when closed, preventing air leakage. The handle’s linear or rotary motion translates to the stem’s movement, enabling reliable and consistent airflow regulation in pneumatic systems.

3.2 Air Flow Control

Manual air valves regulate airflow by adjusting the opening between the valve seat and the stem. This adjustment allows precise control over the volume and pressure of air flowing through the system. Different valve types, such as ball, butterfly, and needle valves, offer varying degrees of control, from simple on/off functionality to fine-tuned throttling. Proper sizing and configuration ensure optimal airflow regulation, making manual air valves essential for maintaining efficiency and performance in pneumatic systems. Regular maintenance is crucial to prevent leaks and ensure consistent control.

3.3 On/Off and Throttle Operations

Manual air valves enable two primary operations: on/off and throttle control. On/off operation involves fully opening or closing the valve to start or stop airflow, while throttle control allows partial opening to regulate flow rates. The valve stem’s movement determines the extent of airflow, with precise adjustments enabling fine control. This dual functionality makes manual air valves versatile for various applications, from simple shut-off to intricate flow modulation. Proper valve seating ensures leak-free operation, while smooth throttling maintains system stability and efficiency.

Applications of Manual Air Valves

Manual air valves are used in industrial automation, automotive systems, medical devices, and HVAC systems to control airflow, ensuring efficient operation and precise system regulation.

4.1 Industrial Automation

In industrial automation, manual air valves play a crucial role in controlling pneumatic systems. They are used to regulate airflow in manufacturing processes, ensuring precise control over actuators and cylinders. These valves enable operators to start, stop, or adjust pneumatic operations, making them essential for maintaining efficiency and safety in automated production lines. Their reliability and durability make them a cornerstone in various industrial applications, ensuring smooth workflow and minimizing downtime.

4.2 Automotive Systems

Manual air valves are integral to automotive systems, particularly in tire pressure management and braking systems. They regulate airflow to maintain optimal pressure, ensuring vehicle safety and efficiency. In braking systems, these valves control the flow of compressed air, enabling precise stopping mechanisms. Additionally, they are used in suspension systems to adjust ride height and stiffness. Their reliability ensures consistent performance, making them vital for both passenger and commercial vehicles. This contributes to overall vehicle safety, efficiency, and driver control.

4.3 Medical Equipment

Manual air valves play a crucial role in medical equipment, ensuring precise control of airflow in life-saving devices. They are commonly used in oxygen supply systems, anesthesia machines, and respiratory therapy equipment. These valves regulate pressure and flow, maintaining patient safety and device functionality. Their reliability is vital in critical care settings, where accurate gas delivery is essential. Manual air valves also help prevent gas leaks and ensure consistent performance, making them indispensable in healthcare applications.

4.4 HVAC Systems

Manual air valves are integral to HVAC systems, regulating airflow and pressure to maintain optimal performance. They are used in ductwork, zoning systems, and ventilation controls to ensure precise airflow distribution. These valves help balance air pressure, preventing energy losses and maintaining consistent temperatures. In heating and cooling systems, manual air valves are essential for adjusting airflow rates and ensuring efficient operation. Their reliability ensures proper air quality and temperature regulation, making them a critical component in both residential and commercial HVAC setups.

Key Components of Manual Air Valves

Manual air valves consist of essential parts like the valve handle, stem, seat, and actuator, which work together to regulate airflow efficiently in pneumatic systems.

5.1 Valve Handle

The valve handle is a critical component of manual air valves, serving as the user interface for controlling airflow. Designed for ease of use, it allows operators to open or close the valve with a simple turn or lever movement. Typically made from durable materials like metal or high-strength plastics, the handle ensures reliable operation even in harsh environments. Its ergonomic design minimizes effort, making it accessible for various applications. Proper handle maintenance is essential to ensure smooth valve operation and longevity. Regular inspection and lubrication are recommended to prevent wear and tear.

5.2 Valve Stem

The valve stem is a vital part of manual air valves, connecting the handle to the valve seat. It transmits the operator’s input, regulating airflow by opening or closing the valve. Typically constructed from durable materials like stainless steel or brass, the stem ensures precise control and longevity. Proper alignment and lubrication are essential to maintain smooth operation. Regular inspection for wear or corrosion is recommended to prevent leaks and ensure reliable performance in various applications. The stem’s design varies depending on the valve type, optimizing efficiency and durability.

5.3 Valve Seat

The valve seat is a critical component in manual air valves, serving as the sealing surface where the valve plug or disc rests when closed. Made from durable materials like brass or stainless steel, it ensures tight shutoff and withstands pressure fluctuations. Proper installation and maintenance are essential to prevent leakage and extend lifespan. The valve seat’s integrity directly impacts the valve’s performance, making it a key factor in reliable airflow control in pneumatic systems. Regular cleaning and inspection are recommended to maintain optimal functionality and prevent operational issues.

5.4 Actuator

The actuator in manual air valves is a mechanical component that converts manual input into valve movement. It is typically a handle or lever that, when operated, moves the valve stem to open or close the valve. Actuators are designed for smooth operation, ensuring precise control over airflow. Durable materials are used to withstand repeated use and environmental factors, making the actuator a critical part for reliable performance in pneumatic systems. Proper maintenance ensures optimal functionality and longevity of the valve.

Installation and Maintenance

Proper installation ensures optimal performance, while regular maintenance, including cleaning and lubrication, extends valve lifespan. Troubleshooting common issues like leaks ensures reliable operation.

Proper installation of manual air valves is critical for ensuring reliable operation. Begin by selecting a location with easy access for maintenance. Ensure the valve is mounted securely to prevent vibration-induced damage. Align the valve’s inlet and outlet ports correctly with the pneumatic system to maintain optimal airflow. Use appropriate threading or flange connections to avoid leaks. Always follow the manufacturer’s torque specifications for tightening. Finally, test the valve under operational conditions to confirm proper function and seal integrity. This ensures long-term performance and system efficiency. Regular maintenance is essential to ensure manual air valves operate efficiently. Start by lubricating moving parts to reduce friction and wear. Clean the valve and surrounding areas to prevent debris buildup, which can interfere with airflow. Inspect the valve stem and seat for signs of wear or damage, replacing them if necessary. Check for air leaks around connections and seals, addressing any issues promptly. In harsh environments, consider more frequent inspections. Always follow the manufacturer’s maintenance schedule for optimal performance and longevity. Common issues with manual air valves include air leaks, sticking parts, and improper closure. To address leaks, inspect and replace worn-out seals or gaskets. For sticking valves, apply a small amount of silicone-based lubricant to moving parts. If the valve fails to close properly, check for debris in the seat or stem and clean thoroughly. In cases of excessive vibration, ensure the valve is securely mounted. Always refer to the manufacturer’s troubleshooting guide for specific solutions to minimize downtime and ensure reliable operation. Manual air valves offer simplicity and cost-effectiveness but may lack precision and automation capabilities, making them suitable for basic industrial and automotive applications. Manual air valves provide straightforward control of airflow, making them ideal for simple pneumatic systems. They are cost-effective and require minimal maintenance. Their durability ensures long-term reliability, and they are easy to install. These valves are suitable for various applications, including industrial automation and automotive systems, offering precise on/off control. Their simplicity reduces the risk of mechanical failure, making them a practical choice for systems where advanced automation is not necessary. This makes them a reliable option for basic control needs. Manual air valves are mechanical devices that require physical operation, limiting their use in automated systems. They lack the precision of automated valves, making them less suitable for applications requiring exact airflow control. Maintenance can be more frequent due to moving parts, and their simplicity may result in slower response times. Additionally, they are not ideal for high-pressure environments or systems needing precise flow regulation. While durable, their limitations make them less versatile for complex or high-precision pneumatic applications compared to advanced alternatives. Proper handling and storage of manual air valves are crucial to ensure safe operation. Always follow manufacturer guidelines and inspect valves regularly for wear or damage. Manual air valves should be handled with care to avoid damage. Store them in a clean, dry environment, away from direct sunlight and extreme temperatures. Ensure valves are protected from contaminants and physical impacts during transportation or storage. Use protective covers to prevent dust accumulation. Always follow the manufacturer’s guidelines for handling and storage to maintain optimal performance and longevity. Proper care ensures reliable operation and extends the lifespan of the valve. Regularly inspect stored valves for signs of wear or corrosion before installation. When operating manual air valves, ensure the system is depressurized before making any adjustments. Wear appropriate protective gear, including gloves and safety goggles, to prevent injury from accidental pressure releases. Always follow the manufacturer’s instructions for operation and avoid exceeding the valve’s pressure and temperature ratings. Regularly inspect the valve for signs of wear or damage, and replace any compromised components promptly. Proper safety measures ensure safe and efficient operation of the valve in various applications. Adhering to these precautions minimizes risks and ensures system reliability. Selecting the right manual air valve involves considering factors like application, flow requirements, and material compatibility to ensure optimal performance and durability in pneumatic systems; When selecting a manual air valve, consider factors like application type, flow rate requirements, and operating conditions. Ensure the valve’s material is compatible with the medium and environment. Assess the port size and configuration to match system requirements. Evaluate the actuation method, whether manual, mechanical, or pneumatic. Additionally, consider pressure ratings, leakage standards, and maintenance needs. These factors ensure optimal performance, safety, and durability in pneumatic systems. Proper selection prevents operational issues and extends valve lifespan. Material selection for manual air valves is critical to ensure durability and compatibility. Common materials include brass, stainless steel, and PVC. Brass is durable and cost-effective, while stainless steel offers superior corrosion resistance for harsh environments. PVC is ideal for lightweight applications and chemical resistance. Consider the operating environment, fluid type, and cost when choosing materials. Ensure compatibility with the system and industry standards to avoid corrosion or leakage. Proper material selection enhances performance and extends valve lifespan in various applications. Selecting the correct size and port configuration for manual air valves is vital for optimal performance. Valve sizes typically range from 1/8″ to 2″ in port diameters. Common port configurations include NPT (National Pipe Tapered), BSP (British Standard Pipe), and SAE (Society of Automotive Engineers) threads. Ensure the valve size matches the system’s flow requirements to maintain efficiency. Proper port alignment and sizing prevent pressure drops and leakage. Always verify compatibility with existing piping and equipment before installation. Correct sizing ensures smooth airflow and system reliability in various applications.6.1 Installation Best Practices

6.2 Regular Maintenance Tips

6.3 Troubleshooting Common Issues

Advantages and Disadvantages

7.1 Benefits of Manual Air Valves

7.2 Limitations of Manual Air Valves

Safety Considerations

8.1 Handling and Storage

8.2 Operating Safety Precautions

Choosing the Right Manual Air Valve

9.1 Factors to Consider

9.2 Material Selection

9.3 Size and Port Configuration